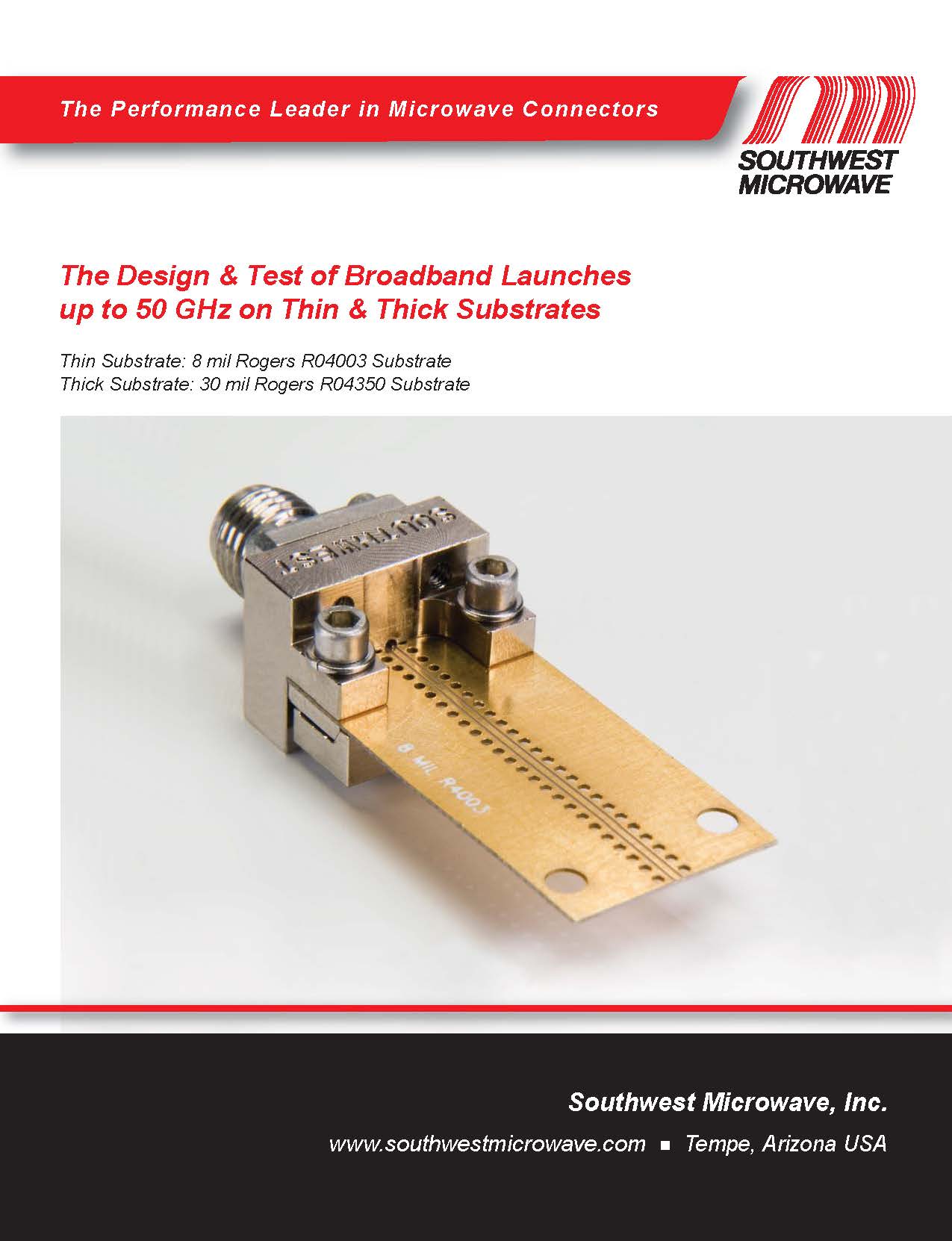

The Design & Test of Broadband Launches up to 50 GHz on Thin & Thick Substrates

This study, carried out by Southwest Microwave, Inc., was conducted in order to explain why their end launch connectors have four distinct pin sizes. The pin sizes, Southwest Microwave explains, are necessary in order to match the right connector with the optimal substrate thickness. As the paper explores and presents the data on the difference in electrical performance between thin and thick substrates, it is determined that in the case of the Rogers 4000 series, the most optimal range of thicknesses is between 8 mil and 30 mil.

Southwest Microwave claims that substrates thinner than 8 mil simply have line widths which are too small to effectively optimize and that once you start getting thicker than 30 mil, the loss of lines increases when higher frequencies are reached. Using three distinct transmission line structures—straight microstrip, top ground microstrip, and ground coplanar waveguide—SMI explores the trade-offs between thin and thick substrates. They conclude that these trade-offs need to be considered when optimizing microwave end launch connections and that, especially with the Rogers 4000 series material, it is best to try and match the connector to the thickness of the substrate.

To see the details of the study, including more detailed explanations of the Southwest Microwave connectors, line structures and all evaluations and assessments, read the whole PDF, provided here for your convenience by HASCO, Inc.

If you'd like to read more, click the image below to download the free PDF.